With the demand for smart, more reliable electrical systems continuing to grow in all industries, the LT vs HT panel question is more important than ever. Whether installing a new industrial facility or replacing a hospital backup power, to modernizing your factory distribution system, understanding the difference between Low Tension (LT) and High Tension (HT) panels in 2025 is important.

This blog will walk you through the latest advancements in LT and HT Panels, contrast the two, and help you make the right choice based on your power distribution needs.

What are LT and HT Panels?

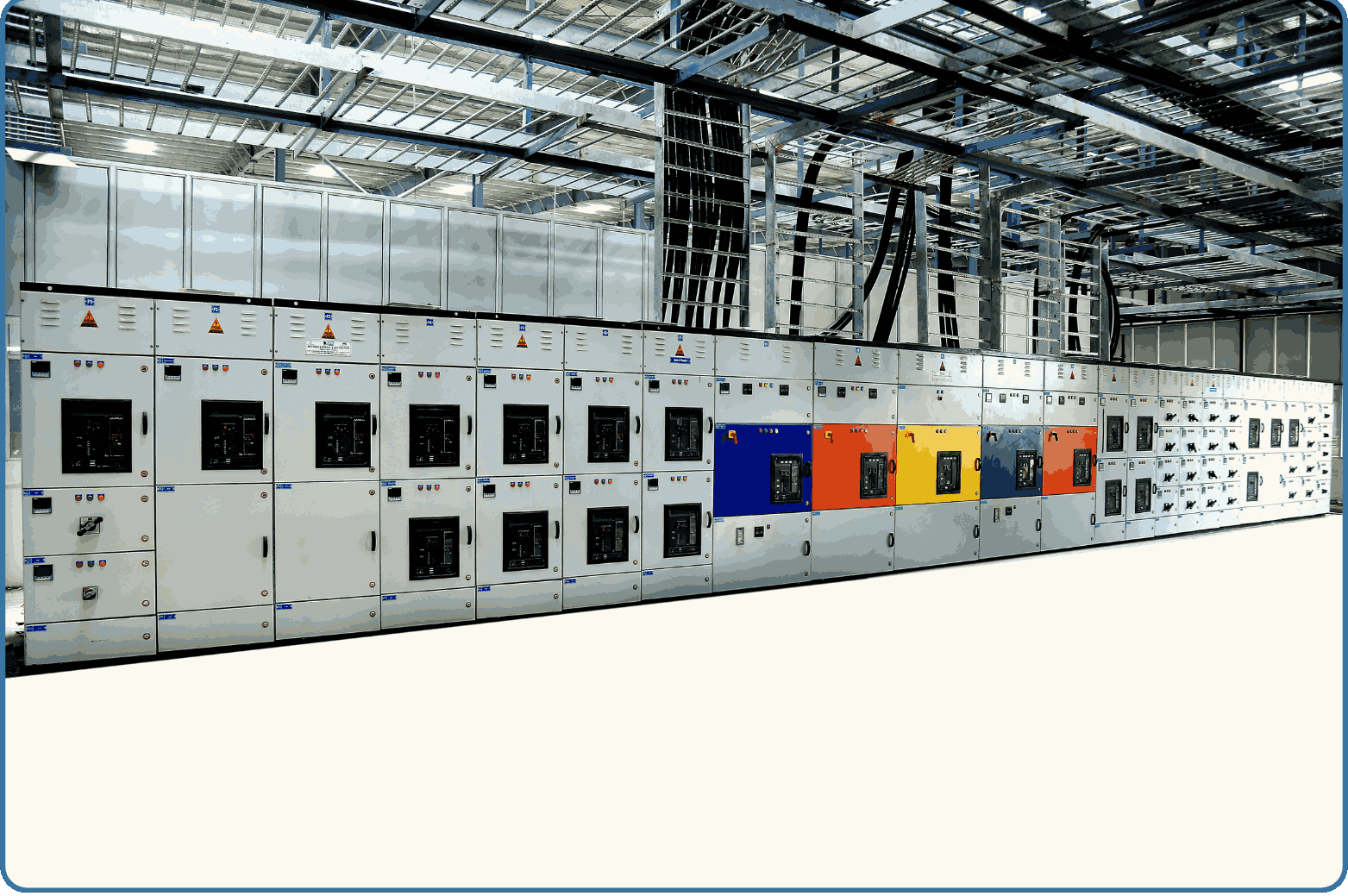

Low Tension (LT) Panels are used in low-voltage electrical systems that operate within a voltage range of not exceeding 1000 volts. They are used in commercial buildings, schools, offices, hospitals, and factories.

High Tension (HT) Panels are meant for usage at higher voltages usually ranging from 11 kV to 33 kV. They are employed in power stations, heavy industries, and high-load distribution.

Both the panels need to efficiently control and supply electrical power but utilized for various load and safety requirements.

LT vs HT Panels: All New in 2025

With the changing technology, LT, along with HT panels, have witnessed plenty of advancements in 2025. Here's what's new:

1. Smart Monitoring Systems

New panels today are being fitted with features that enable real-time monitoring and control. While LT panels are equipped with robust programmable logic controllers (PLCs), HT panels are also being equipped with SCADA-compatible systems.

2. Improved Safety Standards

Safety is always a top consideration, particularly with high-voltage electrical appliances. The 2025 standards now include arc fault detection units, flame-resistant panel enclosures, and automatic shutdown in the event of an overload.

3. Energy Efficiency Improvements

Energy conservation has also been a buzzword in electrical systems. Panels are now available equipped with Automatic Power Factor Correction (APFC) Panels, which ensures facilities have optimal power factor and save on electricity bills.

4. Scalability and Customization

In 2025, panels not only function they're expansion ready. HT and LT panel systems are now both modular, so it's simple to add or change without replacing the whole system.

Key Differences: LT Panels and HT Panels in 2025

| Feature | LT Panels | HT Panels |

|---|---|---|

| Voltage Range | Up to 1,000V | 11kV–33kV |

| Application | Commercial/Small Industrial | Heavy Industrial/Power Plants |

| Installation | Space-saving, indoor | Requires outdoor, sheltered enclosures |

| Maintenance | Low-cost | Requires expert-level maintenance |

| Cost | Affordable | High initial investment |

Where are LT and HT panels commonly applied?

LT Panels Applications: LT Panels are widely used in

- DB[ for residence or commercial office building parties.

- For Shopping Malls and Auditoria Lighting Panels

- Operations Theatre Panels in hospitals require a continuous power supply

- Rural and Municipal Installations Pump Control System Panels

HT Panels are utilized in:

-

Utility companies

-

Mass production plants

-

Power substations

-

Heavy-duty machine shops

When to Use LT or HT Panels

If your building has low power consumption and voltage of less than 1,000 volts, LT panels are the ideal choice. They're cheaper, easier to install, and require fewer maintenance tests. They're utilized widely along with Distribution Boards, Lighting Panels, and Pumping Control System Panels.

But if your infrastructure is handling heavy power loads like a steel plant, refinery, or a large corporate center, HT panels are the best option. They ensure steady voltage supply, handle heavy machinery, and prevent system overload.

Why the Right Panel in 2025 Matters

In 2025, energy consumption in all industries is at an all-time high, and electrical systems have advanced. Selecting the proper panel system is crucial because it guarantees a steady power supply, protects against voltage swings, permits efficient energy use, and prolongs the life of connected devices. Furthermore, contemporary LT and HT panels are also being built to support and contribute to green energy goals as sustainability becomes a top business focus.

Final Thoughts: LT vs HT Panels – The 2025 Outlook

Both Low Tension (LT) panels and High Tension (HT) panels are needed for power distribution in industry. The choice between them depends on your power demand, safety needs, and budget.

With advanced features like APFC integration, smart SCADA control, and custom layouts, it is clear that LT and HT panels have undergone a tremendous change in 2025.

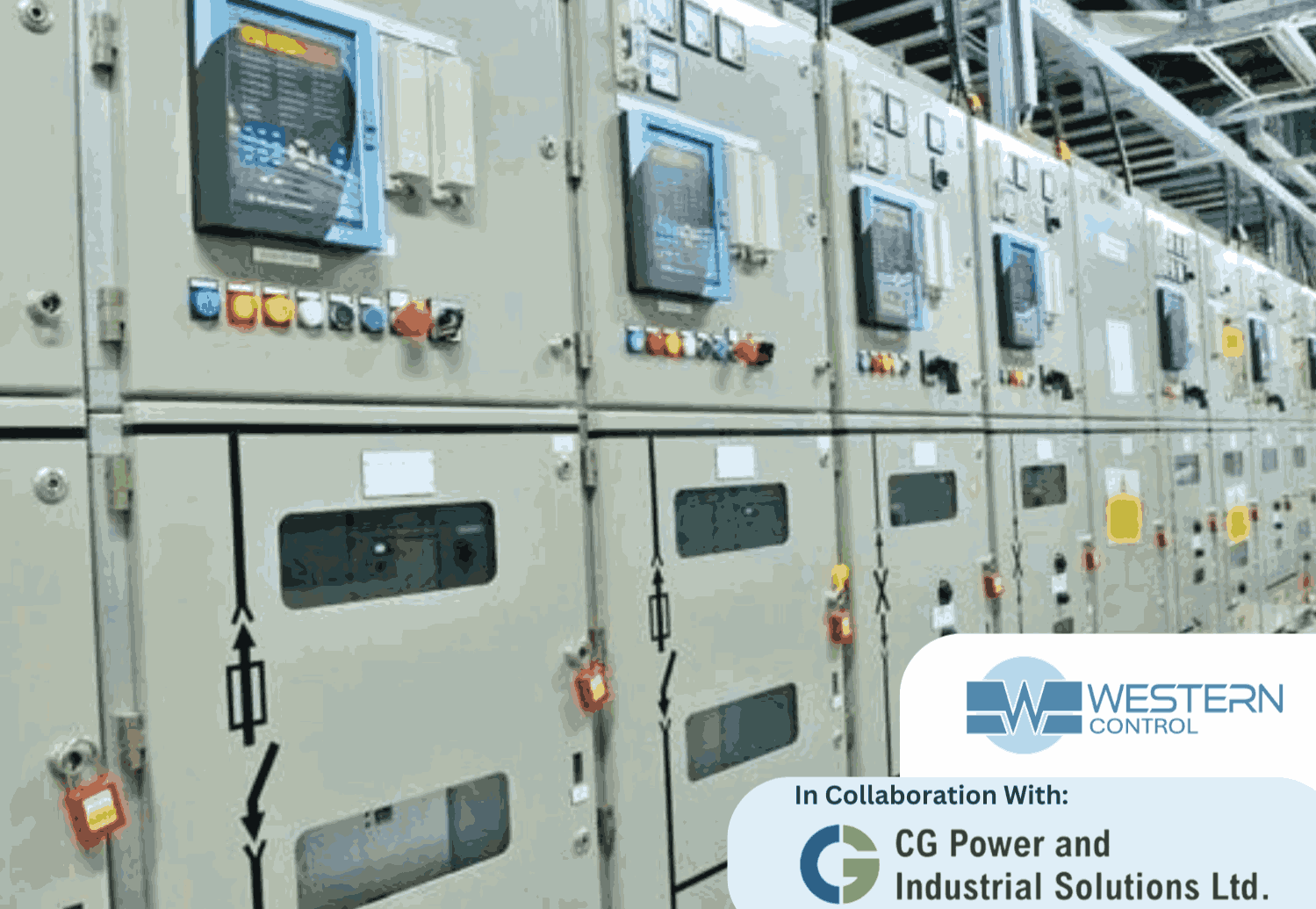

Looking for long-lasting panel solutions?

Western Control is your one-stop solution to high-quality LT Panels, HT Panels, Distribution Boards, Operations Theatre Panels, Lighting Panels, APFC Panels, and Pumping Control System Panels bespoke to meet the electrical requirement of today.

Select Western Control, where security, innovation, and excellence come together in each panel that we provide.