Introduction to HT VCB Control Panels

High-voltage systems play a pivotal role in modern electrical infrastructure, and at the heart of this technology are HT VCB control panels. These panels not only ensure efficient energy distribution but also safeguard equipment from faults and surges. As engineers working with high voltage applications, understanding these control panels is essential for optimizing performance and ensuring safety.

In this comprehensive guide, we will dive deep into the world of HT VCB control panels. From their key components to their operation, maintenance tips, advantages, and applications across various industries—this resource aims to equip you with all the knowledge needed to navigate this crucial aspect of electrical engineering confidently. Whether you're a seasoned professional or just starting your journey in high-voltage systems, let's explore how HT VCB control panels can enhance your projects and operations.

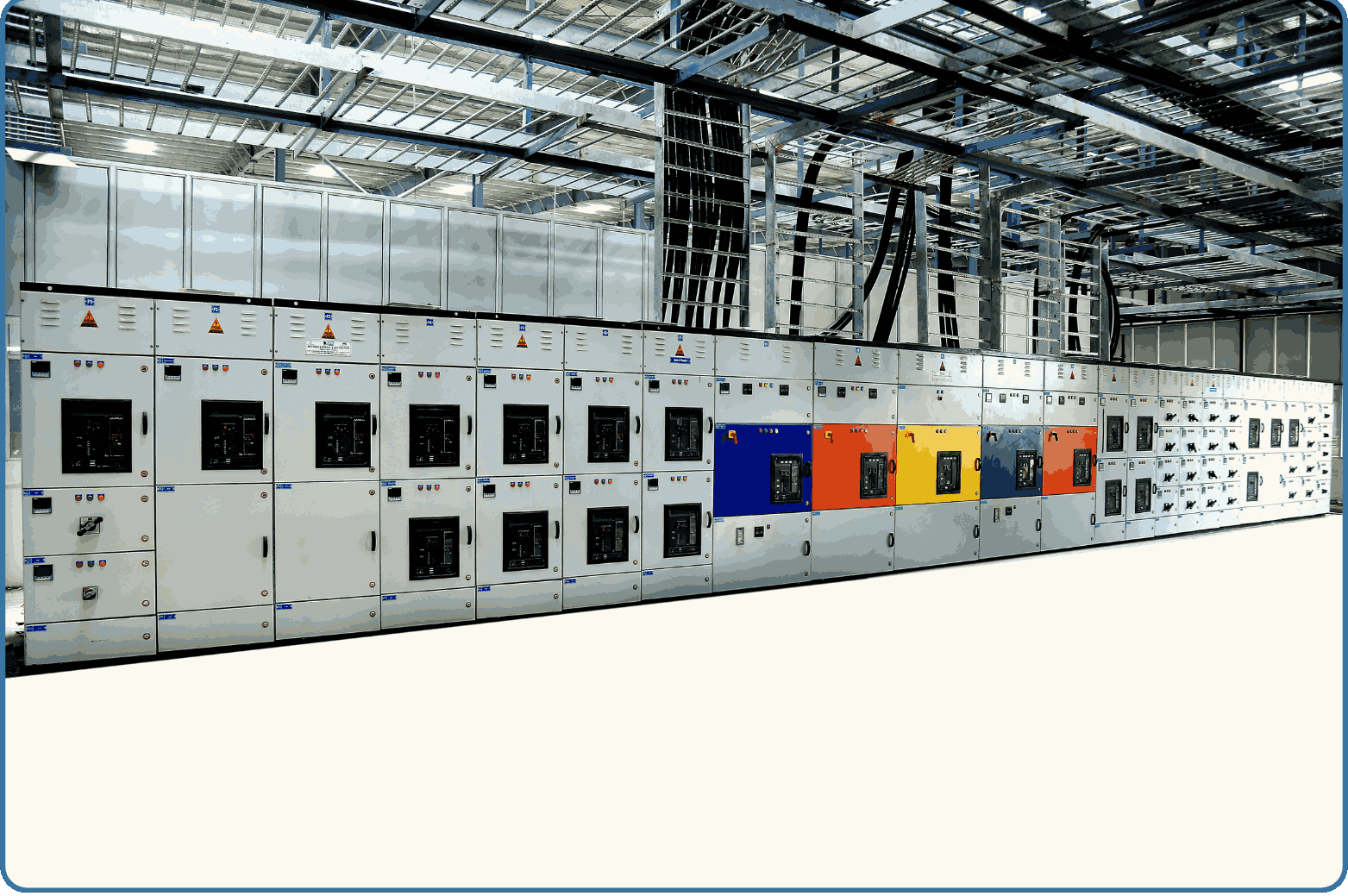

Components of an HT VCB Control Panel

-

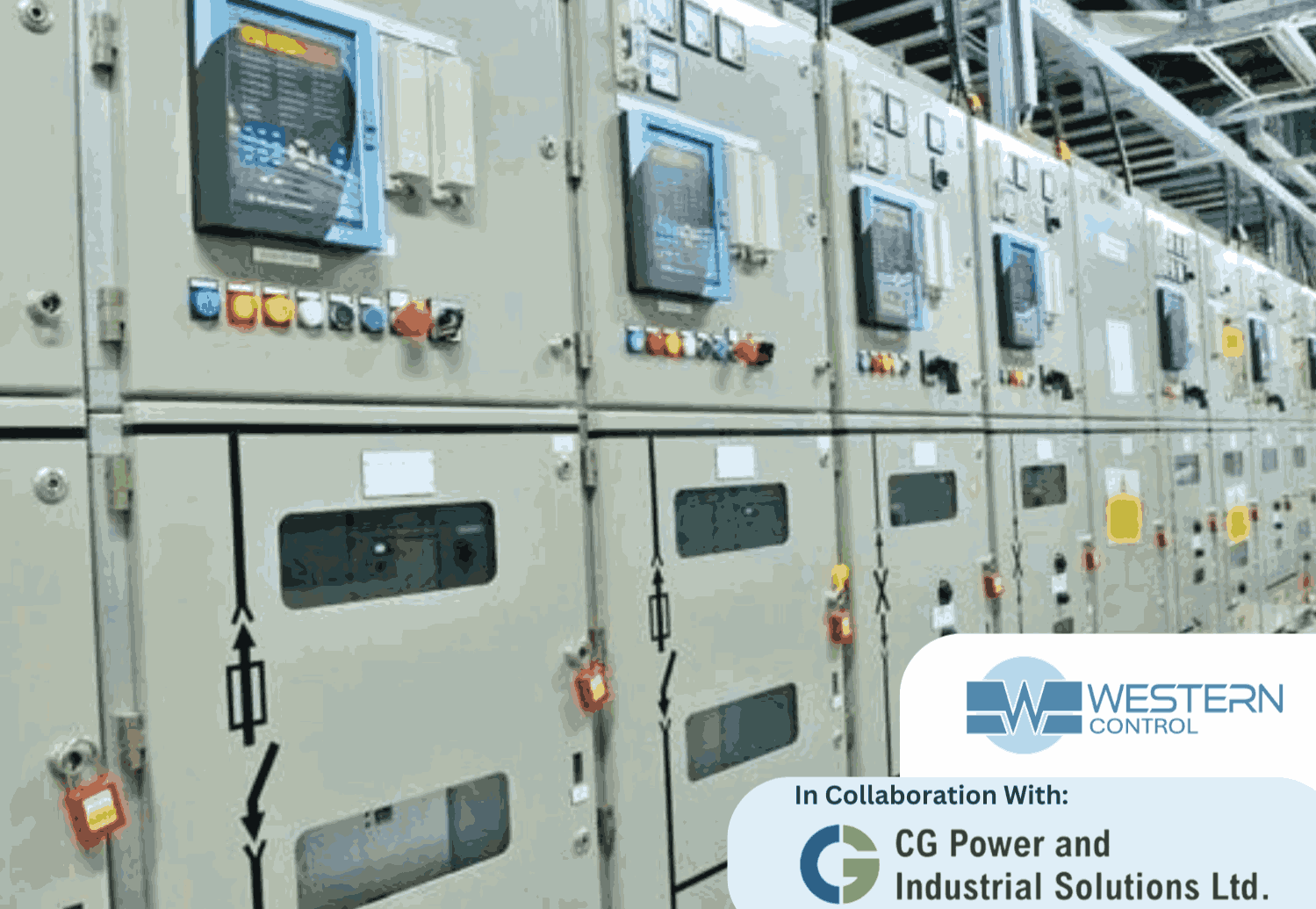

HT VCB control panels consist of several critical components that work together to ensure safe and efficient operation. At their core, they feature a Vacuum Circuit Breaker (VCB), which plays a pivotal role in interrupting the circuit during fault conditions.

-

Another essential component is the control circuitry. This includes relays and timers responsible for monitoring system parameters and providing necessary signals for operation or protection.

-

The panel housing itself is designed to be robust, often made from metal or high-grade plastic materials. It protects internal components from environmental factors while ensuring safety.

-

Additionally, there are various indicators such as LEDs to show operational status. These visual cues help engineers quickly assess the functionality of the system at a glance.

-

Auxiliary devices like current transformers (CTs) and potential transformers (PTs) enhance measurement accuracy and provide vital data for effective monitoring. Each element contributes significantly to the overall performance of HT VCB control panels.

Functioning and Operation of an HT VCB Control Panel

-

HT VCB control panels function as vital components in electrical distribution systems. They primarily serve to protect equipment from overloads and short circuits, ensuring safe operations.

-

When voltage levels rise or a fault occurs, the panel detects these changes through its built-in monitoring systems. The circuit breaker mechanism then activates, quickly interrupting the flow of electricity. This fast response is crucial for preventing damage.

-

These panels incorporate advanced technology such as microprocessor-based relays that enhance reliability. Operators can configure settings easily via user-friendly interfaces, allowing tailored protection strategies for different applications.

-

Maintenance plays an essential role in their operation. Regular testing and inspections ensure all components work effectively. When issues arise, precise troubleshooting methods help identify problems without extensive downtime.

-

This seamless interaction between technology and engineering makes HT VCB control panels indispensable for modern power management solutions across various industries.

Maintenance and Troubleshooting Tips for HT VCB Control Panels

-

Regular maintenance is crucial for the longevity of HT VCB control panels. Start with routine inspections to check for any signs of wear or damage. Look at the insulation, wiring, and connections closely.

-

Keep components clean and free from dust. Accumulated debris can disrupt performance and lead to failures over time. A gentle brush or air blower works well for this task.

-

When troubleshooting issues, always begin by checking the power supply. Ensure that all switches are functioning properly, as simple oversights can cause significant problems.

Pay attention to any unusual noises during operation; they often indicate underlying mechanical issues. Documenting these occurrences helps in pinpointing recurring faults. -

For more complex challenges, consult technical manuals specific to your model. They provide essential insights into error codes and recommended solutions tailored to your equipment's design.

Advantages of Using HT VCB Control Panels

-

HT VCB Control Panels offer numerous advantages that make them a preferred choice in electrical systems. One of the primary benefits is their ability to interrupt high voltage faults quickly and efficiently, ensuring safety and reliability.

-

These panels are designed with advanced technology, which enhances their performance. They provide excellent insulation properties and reduced risk of electrical arcing, leading to prolonged equipment life.

-

Another significant advantage is their compact design. This allows for easier installation in limited spaces without compromising functionality or safety standards.

-

Moreover, HT VCB Control Panels come equipped with various monitoring features. These features facilitate real-time data collection, enabling engineers to make informed decisions regarding system operations.

-

Cost-effectiveness adds to their appeal as well. Reduced maintenance needs translate into lower operational costs over time while maximizing uptime and efficiency across industrial applications.

Applications and Industries that Utilize HT VCB Control Panels

-

HT VCB Control Panels find their place across a wide range of industries, proving essential for reliable electrical distribution and safety.

One primary application is in power generation facilities. Here, they manage high voltage circuits that are crucial for the generation process. -

The manufacturing sector relies heavily on these panels to safeguard machinery and streamline operations. Factories often experience fluctuations in demand, making VCB control panels indispensable for maintaining consistent performance.

-

In infrastructure projects like airports and railways, HT VCB Control Panels provide the necessary protection against faults, ensuring smooth operation of critical systems.

-

They also play an important role in renewable energy sectors such as wind and solar farms. By managing high voltage outputs efficiently, these panels contribute significantly to sustainable energy solutions.

-

Telecommunications centers utilize them too; uninterrupted power supply is vital for communication networks to function effectively without downtime.

Future Developments in HT VCB Control Panel Technology

-

The future of HT VCB control panels is poised for significant advancements. Emerging technologies such as IoT (Internet of Things) are set to revolutionize how these systems operate and communicate.

-

Smart features will allow for real-time monitoring, enabling predictive maintenance. This shift could reduce downtime and enhance reliability in industrial settings.

-

Moreover, the integration of AI algorithms may optimize performance by analyzing data patterns. Such developments can lead to more efficient energy management and reduced operational costs.

-

Advancements in materials technology promise lighter, more durable panels that withstand harsh environments. These innovations ensure long-lasting performance while enhancing safety standards.

-

As sustainability becomes a priority, manufacturers are exploring eco-friendly designs and components too. The focus on energy efficiency will likely drive the evolution of HT VCB control panels into greener solutions for modern industries.

Conclusion

HT VCB Control Panels play a vital role in the management and protection of electrical systems. Their ability to handle high voltage circuits with efficiency and safety makes them indispensable in various industries. As technology continues to advance, these control panels are evolving, integrating smart features that enhance performance and monitoring capabilities.

Engineers must stay informed about the components and operations of HT VCB Control Panels for optimal use. Regular maintenance is essential for ensuring longevity and reliability. Understanding troubleshooting techniques can make a significant difference when faced with operational challenges.

With their diverse applications—from power generation to manufacturing—these control panels are integral to modern infrastructure. The future promises even greater innovations, making it an exciting time for engineers involved in electrical design and implementation.

As we look ahead, embracing advancements in HT VCB Control Panel technology will be crucial for those dedicated to pushing the boundaries of electrical engineering excellence.