An Overview of HT Panels

HT Panels are key components of cutting-edge electrical systems. But as all systems do, they need to be modified for the needs of the industry. HT panels provide the industry with the most effective, robust, and safest solution to meet the required needs.

From engineers searching for dependable high voltage solutions to facility managers wanting to improve and update systems, this overview will provide the best possible understanding for all. And with the understanding that the world of HT panels has more to offer in the world of developing electrical technologies, we will untap this powerful source in solving your electrical issues.

Getting to Know High Voltage Solutions

-

The need for high voltage solutions span all industries. These solutions provide efficiency and reliability at the highest possible level. These high voltage systems transport electricity along extensive distances with very little energy loss.

-

The principles concerning high voltage systems are complex. A variety of electrical principles and safety measures must be implemented to tackle the risks concerning possible high voltages.

-

HT panels are essential to our line of business because they provide strong safety and control for electrical distribution networks to ensure customers get the right electrical power.

-

HT panels are designed for the current and future needs of customers. High-voltage technology even empowers and reduces operational costs for customers from substations to industrial plants.

-

As the industries change, so do the technologies that improve high-voltage solutions. HT panels are constantly evolving to ensure they are the best option for efficient power management in any industry

Advantages of HT Panels

-

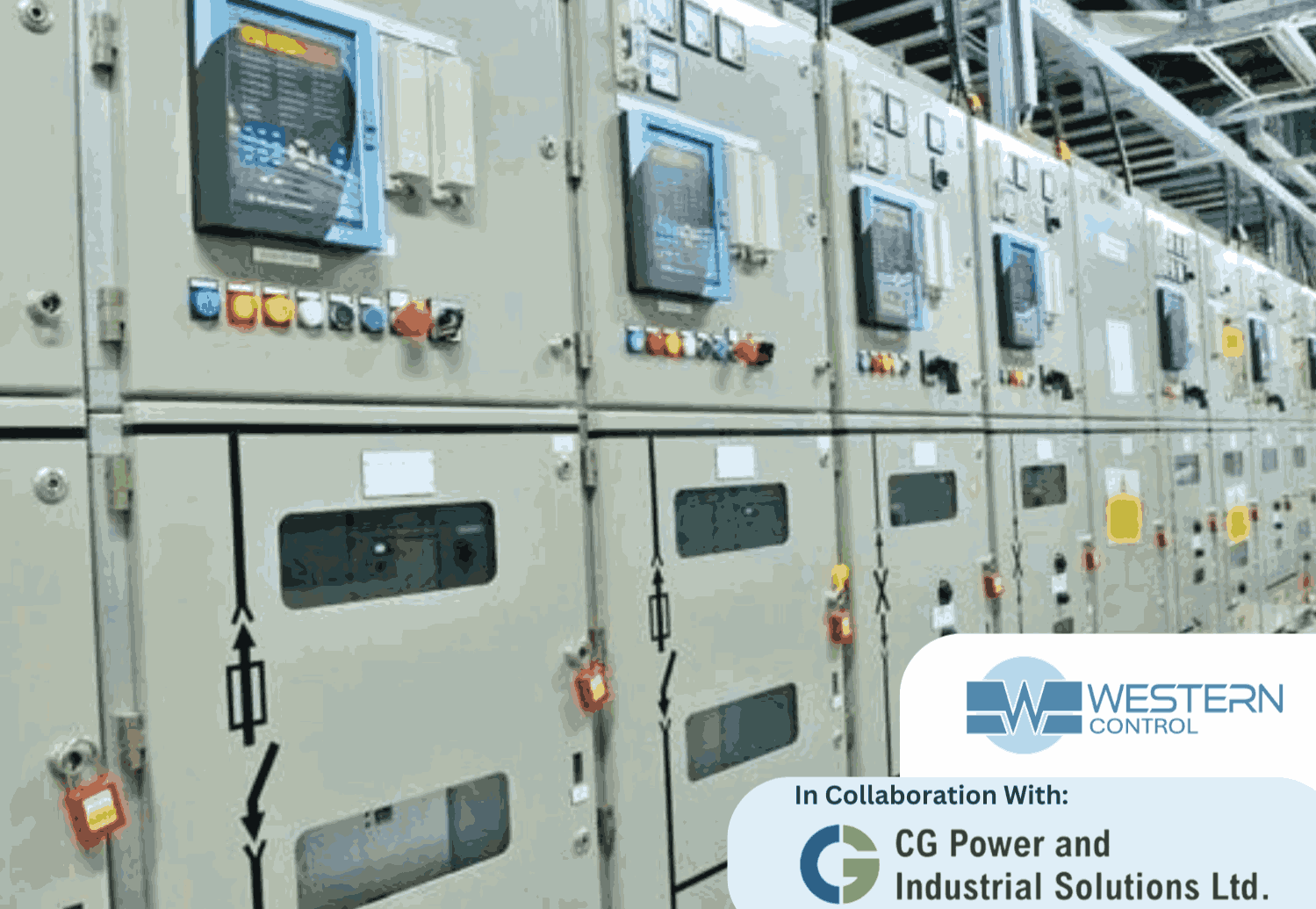

HT panels are essential to modern electrical systems for a variety of reasons. They are the most efficient in providing safety features for electrical systems. The critical insulation and protection from short circuits provide protection from electrical hazards.

-

They are designed to handle large loads and high-voltage currents without the risk of overheating. HT panels are designed to perform reliably even under the most demanding conditions.

-

They are designed to endure extreme operational conditions like high humidity and dust to ensure a long operational lifespan.

-

Finally, HT panels are designed to improve energy efficiency by optimizing electrical power distribution to reduce gaps in the electrical power supply.

-

Because of their compact design, many units can be installed in tighter, more restricted spaces, while still maintaining an unblemished operation and user accessibility. This factor alone provides units with a varying range of applications across industries.

Varieties of HT Panels

-

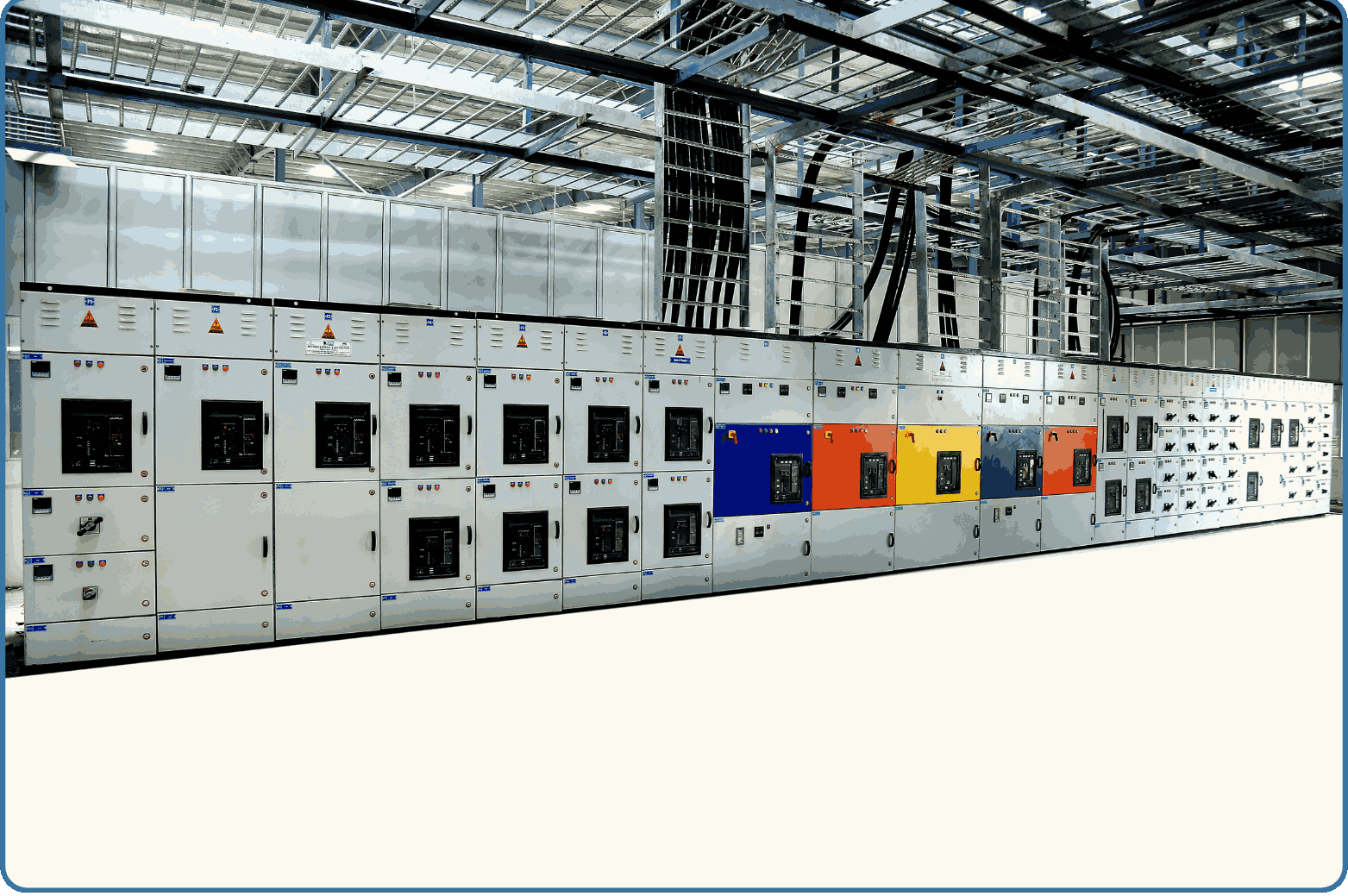

Offering a wide range of industrial-specific solutions, HT panels can be differentiated into distinct types. Indoor HT panels, for example, are among the most common panels. These panels can be installed in the interior of a building, and shield users from external environmental elements.

-

In contrast, Outdoor HT panels can be exposed to elements outside, and are built to resist more extreme, harsher weather. Advanced elements, like a casing that protects from rain, dust, and extreme temperatures, are incorporated into the design in order to protect the internal elements of the panel, providing a more reliable Outdoor HT panel that can be exposed to the outdoors.

-

Modular HT panels are also important. These units are customizable, and can be configured in a variety of ways. This flexibility makes them suitable for projects that depend on the expansion of the unit in the future, or projects that require more scaling in the future.

-

Another variety is compact HT panels which are design to save space, without compromising any of the units abilities. These units are is also designed to ensure seamless integration into existing systems, providing units a large suitable area to work in. With distinct sets of functions assigned to varying HT panel types, the selection of panels can be determined by operational needs and environmental factors that the selection is to be based around.

How to Choose an HT Panel That Works for You

-

When selecting HT panels, careful choice is needed for panels that best fit your needs, as a lot of variables come into play. First, figure out your panel power requirements. Specify what voltages need to be handled along with your operational load requirements.

-

Second, analyze what HT panels you need based off your operational environment. Identify if the HT panels will be installed indoors, or exposed to the outdoors. HT panel protection must be tailored to extreme heat, moisture, or precipitation.

-

Third, analyze what national safety code requirements are needed to protect people along with the panels as you evaluate your operational safety.

-

Fourth, it is equally important to avoid designing panels that will require modification to the HT panels for future operational extensions.

-

It may be wise to consult with a panel expert as these variables can stray into the operational improvements of the future, along with customizing the best panels for current operational needs.

Installation and Maintenance of HT Panels

-

Installing HT panels as some technical needs to be met, and the guidelines provided by the manufacturers along with local jurisdiction need to be met to ensure longevity and safety.

-

Optimizing the placement of HT panels in a ventilated area void of excessive moisture or dust is important to ensure the HT panels function optimally. These panels will need to be mounted securely, and avoid any shifting from dust or moisture that may accumulate to avoid any negative impact from external conditions.

-

Maintenance is crucial for efficiency in operations. Regular checks help spot early signs of trouble or damage before they become bigger problems. Cleaning parts can help improve dirty, underperforming components.

-

Routine testing also helps ensure everything is in working order and meets safety standards. To help with future troubleshooting, documenting tests and inspections creates an accurate history.

-

Making sure staff understand operational protocols helps emphasize best practices when working with HT panels, improving safety and efficiency in the facility.

Case Studies: Real Life Applications of HT Panels

-

HT panels have demonstrated their effectiveness in many different sectors. In one manufacturing facility, the use of HT panels optimized the power distribution process, resulting in operational efficiency and reduced downtime.

-

Another example is a large renewable energy project that utilized HT panels for the transmission of solar energy. The high-voltage solutions offered seamless grid integration, thereby enhancing performance.

-

Furthermore, in urban development, HT panels help smart cities by efficiently controlling electrical loads. They also provide reliable and flexible power supply options to meet future growth requirements.

-

An example is an industrial park that used HT panels to meet growing energy demands. This provided additional safety and cost efficiencies across the park.

-

HT panels exemplify versatility and applicability in all modern electrical systems. Their adaptability earns them a spot in current and future tech advancements.

Potential Innovations in High Voltage Technology

-

The ever-changing landscape of high-voltage technology is driven by innovations that push the limits on efficiency and safety of electrical systems.

-

The future of HT panels in smart grid technology is seamless. Connectivity in the smart grid enhances reliability and decreases outages. The combination of IoT and high voltage technology is bound to create new opportunities for businesses.

-

The use of sustainable materials is continually being developed. Many manufacturers attempt to use sustainable materials that perform as well as conventional products.

-

The insulation materials also promise improvements to the safety of the HT panels. Innovations in these materials withstand a greater range of conditions, improving the performance and longevity of the panels.

-

The use of digital twins is also becoming more common. Digital twins allow for modeling and performance simulation of the HT panels in numerous scenarios, resulting in better outcomes of the HT panels as they are built.

-

Given the above developments, HT panels are bound to play a significant role in future developments of energy infrastructure.

Conclusion

HT Panels have proved to be foundational in constructing high-voltage solutions technology. They provide reliable and safe performance for various applications. Users can choose from types of panels, such as metal-encased or outdoor, to ensure their specific needs are met.

The advantages of the HT Panels are clear. Indirectly, their high voltage capability means they can be used in manufacturing, power generation, and distribution. They improve the reliability of the systems and over the long run lower the costs of maintenance.

Proper choice of panels involves extensive evaluation of the load requirements, and conditions of the environment. Performance is improved by proper maintenance and installation models.

The advancement of technology is predictable as HT Panels are likely to have improved designs for more efficient performance. These tools will power industries, and our worlds in safer, more efficient ways.